If you’re like most, this is your first window purchase. And while this is a project that many undertake to make their home more energy-efficient, it’s also the perfect opportunity to transform your most personal space into one that reflects your specific style and taste.

This guide is designed to help you understand the various window styles available – from a traditional double-hung model to sleek casements and room-expanding bay and bow windows.

Is there a big difference between custom windows and ready-made windows at a building supply store?

For the best fit, you should strongly consider custom-sized windows. Custom windows are precision-engineered to 1/8″ increments and manufactured to fit your specific window opening.

You will get the exact style and options you desire, ensure utmost energy efficiency, and an overall better appearance and installation. Stock-sized windows are adjusted to fit your existing window openings on site and may require extensive carpentry work both inside and outside your home. The appearance and thermal performance can this retrofitting process.

In terms of construction, what makes for a better grade, more durable vinyl window?

The corners of the window frame and sashes should be fusion-welded (heat-welded) for a weathertight construction. Beware of windows with mitered corners screwed together or chemically welded corners, as they may decline in performance over time. You’ll also want to take a look at the vinyl extrusions in the window frame and sash. At a quick glance all vinyl windows may look similar, but there can be dramatic differences in the quality of the vinyl used.

Some windows, built with lower-quality vinyl that has a dull blue or gray cast, can become brittle over time. Alside Windows are constructed with premium vinyl extrusions to ensure the frame and sashes provide long-lasting beauty and performance.

What other construction features should I be aware of?

When you compare one window to the next, you’ll see – and feel –the quality difference. Alside Windows begin with a computer-controlled construction of the mainframe and steel-reinforced sash to produce a solidly built window with superior strength. Most windows come standard with double-strength glass for an exceptionally strong barrier.

Interlocking meeting rails and thickset multi-chambered extrusions further add to the structural integrity and insulation, while multi-layer weatherstripping, a compression bulb seal and drop-in glazing provide excellent thermal protection.

You’ll also want to test the window’s moving parts. Alside Double-Hung Windows, for example, feature a full interlock at the meeting rails to seal the window tightly shut and a constant force balance system to ensure smooth and easy operation of the moving sash.

What should I look for in terms of glass performance?

For starters, many windows are built with single-strength glass. Alside Windows are built with double-strength glass, which means that each pane is 3 mm thick instead of the industry standard of 2 mm. The glass is stronger, more protective and won’t crack or break as easily.

Windows are about 80% glass, so it’s important to select a glass package that will help shield your home from absorbing outside heat in the summer and losing indoor heat in the winter. For optimum energy savings consider Alside Windows with the ClimaTech® insulated glass package. ClimaTech combines Low-E glass with argon gas and the Intercept® Warm-Edge Spacer System to achieve optimal energy efficiency.

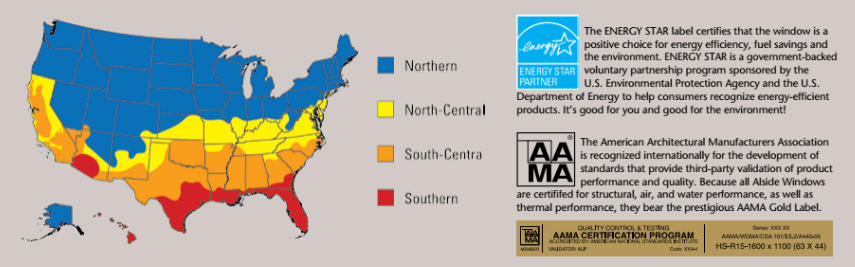

Because Alside offers a variety of ClimaTech glass packages, your window professional can help you choose the best one for your home and area of the country.

Are replacement windows a good investment?

From day one, Alside Windows begin making a return on your investment. You can expect a decrease in your annual fuel consumption for heating and cooling your home. Vinyl windows are virtually maintenance-free, which can also save substantial dollars spent on painting, caulking and maintenance. New windows will enhance the curb appeal of your home, which can help increase its resale value. In most cases, you can expect to recover more than half of the cost of your replacement windows when it’s time to sell.

The national average of the cost recouped for vinyl replacement windows is 71.6% for midrange projects and 72.6% for upscale projects, according to Remodeling magazine’s “2010-11 Cost vs. Value Report.”

Should I be concerned with where the windows are manufactured?

Absolutely. A replacement window is only as good as the company that stands behind it. Alside has more than 60 years of manufacturing experience and success. We proudly own and operate six window plants in North America that expertly produce windows of superior beauty, quality and durability. Utilizing performance standards beyond AAMA, ASTM and NFRC requirements, our windows are rigorously tested for air, water, structural load, thermal performance, and forced entry resistance. Companywide, we are committed to ensuring that each window will provide years of excellent service and energy savings.

We also stand behind our products long after the installation is complete with a knowledgeable customer service team that’s ready to serve you. Should any questions or concerns arise, just call the number on the sticker located on your window. This label also includes a factory order number for easy reference.

What about warranty coverage?

Alside Windows are backed with a Lifetime Limited Warranty with transferability provisions – further assurance that you have made an excellent selection for your home from a respected manufacturer.

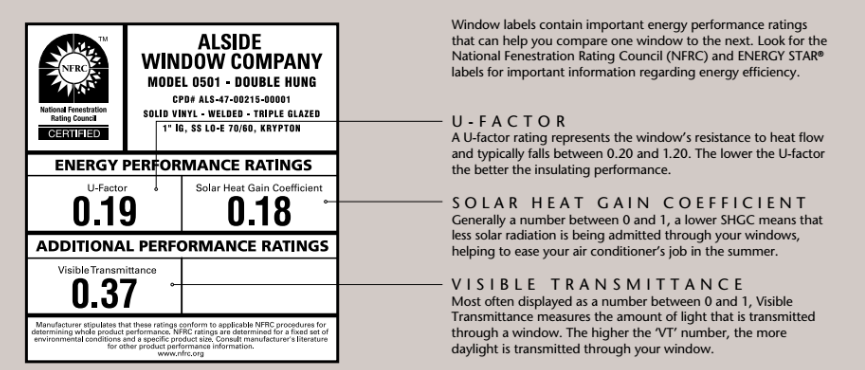

Energy Performance Ratings

What Makes One Glass System Better than Another?

Insulated Glass – a combination of two or more panes of glass with hermetically sealed air space between.

Argon Gas – a safe, colorless, odorless, nonflammable, nontoxic inert gas that is heavier than air. This insulating gas between the panes of glass counteracts heat/cold conduction. It also helps reduce noise infiltration – so your home will be more energy-efficient and quieter.

Krypton Gas – this super-insulating gas is denser than argon and therefore, provides better performance properties.

Low-E Glass – a special type of glass with microscopically thin, undetectable metallic coatings applied to its surface that act as a thermal barrier. In winter months, Low-E helps reduce heating costs by reflecting indoor heat back into the room. During the summer, Low-E lets in visible sunlight while minimizing infrared and ultraviolet solar energy that can increase cooling costs and cause curtains, carpets and furniture to fade.

PPG Intercept Warm-Edge Spacer System – a sealed, one-piece alloy in a U-channel design that creates an effective thermal barrier to reduce conducted heat loss through the window.

The Intercept Warm-Edge Spacer keeps the edges of the window glass warmer and reduces condensation problems around the window perimeter.

High R-Value – R-value is the resistance to heat flow, so the higher the R-value the better the insulating performance.

Low U-Factor – U-factor (also referred to as U-value) represents the rate of heat flow through a glazing system. The lower the U-factor, the greater the resistance to heat flow and the better the insulating power.

SHGC – Solar Heat Gain Coefficient represents the fraction of solar radiation admitted through a window. The lower the SHGC, the less solar heat the window transmits into the home, which can help reduce air-conditioning costs during summer months.

Energy Glass Upgrades – for even greater energy savings, ask about Alside’s ClimaTech high-performance glass packages with additional energy-efficient features.